ARC ECO Fuel

Production Technology

3-Process Steps to ARC Ultra

01

Biomass Feedstock Engineering

02

02

Feedstock Conversion to Raw Diesel

03

Raw Dielsel Refined to ARC Ultra Quality

1. Feedstock Pretreatment

Feedstock preparation is a critical part of ensuring that ARC ECO fuels meet the world’s highest standards for transportation fuel using imperfect biomass raw materials including waste wood, industrial waste, and municipal solid waste (MSW) which all come in a wide variety of shapes, sizes, contaminant levels and moisture content.

Fortunately, our feedstock processing partners can engineer the feedstock for optimal performance in the ARC ECO fuel production process by sizing, shaping, treating and drying the biomass as required.

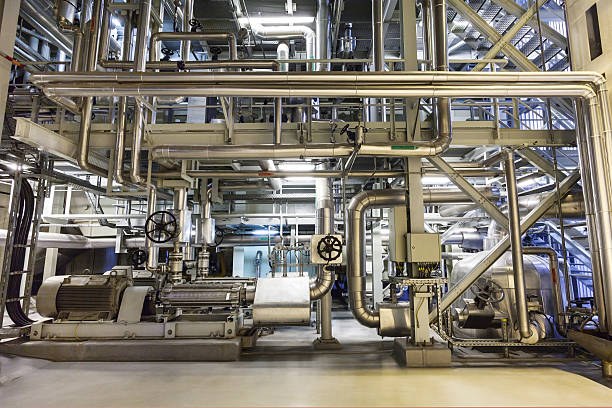

2. Fuel Production Reactor

Our premier biomass conversion system partner provides state of the art, high temperature pyrolysis technology, capable of converting a wide range of engineered biomass feedstocks into synthesis gases hydrogen rich synthesis gas which is exposed to a high temperature chamber (>1000 degrees C) which produces a gaseous aerosol that when liquified, is a stable, and bona fide raw diesel fuel. AEG designed a downstream customized, refining, impurity removal and polishing system that produces a PREMIUM ROAD FUEL (85%+/-) and AVIATION FUEL (15% +/-). There is also a stream of byproducts that include all natural agricultural products including wood vinegar and PREMIUM quality biochar.

3. Commercial Transportation Fuel Production

ARC ECO has designed a trade-marked “back-end” fuel clean-up process for raw biomass-produced synthetic diesel. Our clean-up process is cost efficient, environmentally friendly and produces the highest quality of developmental fuel exceeding American and International specification for diesel fuel and renewable diesel fuel including ASTM D975, EN 590, and EN 15940 that covers HVO fuels.

Due to our technology adancements, our process is energy efficient and significantly reduces air emissions while removing virtually all sulfur and other fuel contaminants.

Puriphlo Ionic Systems

AEG tasked its Director of Technology and his AEG affiliates to design a downstream system that would optimize ARC fuel values through advanced processing and refining of the raw diesel fuel. The resulting Puriphlo System was designed to remove all impurities present in the raw diesel fuel (impurities defined as anything that had a negative effect on fuel quality or performance). This includes inert contaminants, aerobic & anaerobic bacteria, sulfur and aromatics. Therefore, Puriphlo is the technology that transforms the Proton raw diesel fuel to ARC ECOfuel Ultra quality standards. It is a hybrid technology that consists of advanced distillation and an ionic fluid refining & polishing process creating the following Ultra features:

- ETrace Sulfur

- ELow Aromatics

- ETrace Impurities

- EHigh Performance

- EOptimum Carbon Savings